What Are Steel Riding Arenas?

The weather can put a damper on any horse training or riding session. However, steel riding arenas provide a covered and enclosed space for these activities, regardless of what’s happening outside. In turn, this means no cancelled lessons, no mud-soaked feet, and no seasonal shutdowns. This guide covers design options, advantages over traditional arenas, and what to consider when planning your steel riding arena.

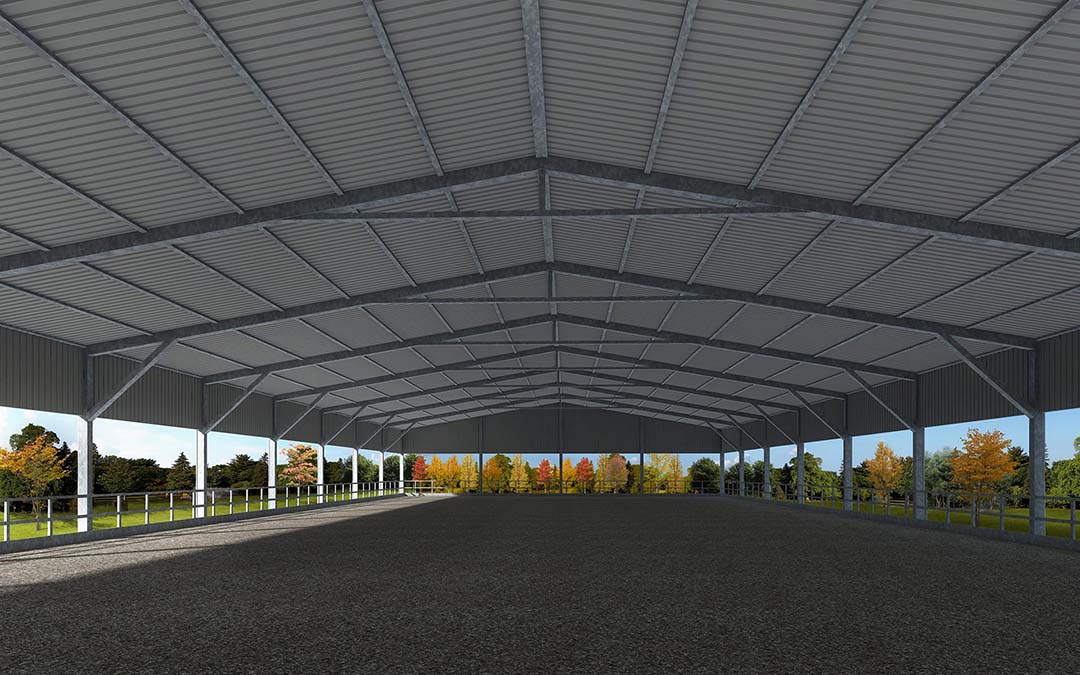

Steel riding arenas are pre-engineered metal buildings designed for equestrian use. The biggest advantage of steel at this scale is its clear-span capability, which covers large open areas without interior columns or posts getting in the way.

This unobstructed space works for dressage, jumping, barrel racing, general exercise, lesson programs, clinics, and competitions. Whether you’re running a private barn or a full boarding operation, the structure stays out of the way and lets you use the space how you need to.

Key Benefits of Steel Riding Arenas

- Cost-Effective Long-Term: Lower maintenance and energy costs make steel riding arenas more cost-effective than most alternatives.

- Year-Round Riding: No matter whether it’s raining, snowing, windy, or extremely hot, none of it shuts you down. An indoor riding arena keeps your schedule consistent.

- Superior Durability: Steel doesn’t rot, warp, or attract pests. In fact, a well-maintained steel horse arena can stand for 40 years or more without major structural issues.

- Clear-Span Design: Clear-span framing means no interior posts to navigate around or hazards standing in the way.

- Low Maintenance: There’s no wood to paint, treat, or replace. The building essentially takes care of itself outside of basic annual checks.

- Weather Protection for Horses: The area protects your animals from the elements, keeping them safe and comfortable.

- Better Footing Preservation: A covered riding arena protects your investment in arena footing. No rain turning it to mud, no freeze-thaw cycles breaking it down, and no constant reworking after every storm.

- Excellent Ventilation Options: Despite being covered, ridge vents, sidewall openings, and fan systems keep air moving, controlling dust and keeping the environment comfortable.

Design Features & Specifications

Size & Dimensions

Arena size depends on your primary discipline. A small dressage court runs 66’ x 131’. A full-size dressage arena stretches to 66’ x 197’. Jumping arenas need at least 100’ x 200’ . Multi-purpose setups usually fall in the 80’ x 120’ to 100’ x 200’ range.

On top of this, you’ll also want to account for ceiling height. Plan for at least 16 to 20 feet of clearance minimum for comfortable mounted movement and jumping. If you want spectator seating, factor that into your width as well.

Door & Entry Options

Ideally, horse entry doors should be at least 12 to 16 feet wide, with large sliding or bi-fold doors being most common. Multiple entry points improve safety and traffic flow, especially during lessons or events. Meanwhile, walk-through doors can handle everyday foot traffic.

Ventilation & Lighting

Good airflow is important for riders, spectators, and animals alike. As such, ridge vents paired with sidewall vents create natural circulation that manages dust and heat.

Additionally, translucent roof panels or skylights can help bring in natural light during the day, and LED fixtures can light up evening sessions without a harsh glare.

Insulation & Climate Control

In colder regions, insulation keeps the space usable through winter and prevents condensation on the ceiling.

In contrast, for hot climates, ventilation and fan systems do most of the work. However, condensation control should be part of the plan regardless of where you’re building, as it can occur due to both humidity and other extreme climatic conditions.

Steel vs. Other Arena Types

Steel isn’t the only option, but it handles the demands of equestrian use better than most alternatives.

Compared to wood-framed arenas, and as aforementioned, steel doesn’t rot, warp, or invite termites. It requires less upkeep, spans wider distances with fewer supports, and offers better fire resistance.

Compared to fabric or tension structures, a metal riding arena is more permanent, handles heavier wind and snow loads, insulates better, and holds higher resale value. Fabric structures work for temporary or budget setups, but they don’t match steel’s durability.

And compared to riding outdoors, the difference is obvious. Protected footing, consistent conditions, and year-round access make a covered arena for horses a real operational upgrade.

Maintenance & Longevity

Steel riding arenas are about as low-maintenance as a building this size can be. In fact, often for maintenance, annual inspections, gutter cleaning, door track lubrication, and seal cover checks are all that is needed.

However, for arena footing maintenance, you will still need to drag regularly, water as needed, and refresh periodically. But this will, luckily, be less impacted by the elements due to the coverage an equestrian arena building offers.

Planning Your Steel Riding Arena

Step 1: Assess Your Needs

Start by identifying your primary discipline and how the arena will be used day to day. Consider how many horses will use the arena, any needs for spectators, storage, or tack rooms. Also, future planning may be important, such as expansion down the road.

Step 2: Consider Your Budget

Steel riding arena costs typically range from $40,000 for smaller, simpler builds to $150,000 or more for large, fully equipped facilities. Factors impacting these costs include size, insulation, doors, location, and site prep. And don’t overlook the extras that add up, such as footing material, drainage work, lighting, and permits.

If you generate revenue from events and lessons, long-term ROI is also worth considering, as it can help ensure the building essentially pays for itself over time.

Step 3: Permits & Zoning

Check your local agricultural building codes before committing to any one design. This will include any setback requirements from property lines and even HOA restrictions (if applicable). Reputable suppliers, such as US Patriot Steel, can often help you navigate this process early on.

Step 4: Site Preparation

The ground needs to be level, along with careful drainage planning (a common oversight). This is where choosing your foundation, such as a concrete perimeter, a gravel base, or engineered fill, is important.

On top of this, keep in mind that footing installation is a separate cost from the building itself and should be factored into your cost and timeline from the very start.

Get A Free Custom QuotePopular Applications & Uses

Multi-Use: Equestrian facilities serve a wide range of purposes beyond simply housing horses. Many operations utilize their space for off-season equipment storage, livestock shelter, or hosting farm events, making them a versatile investment for any property.

Training Facilities: Professional training barns and lesson programs rely on well-designed facilities to support their work. A thoughtfully planned space ensures both horse and rider can develop their skills in a safe and functional environment.

Boarding Operations: Boarding facilities depend on a well-structured design to provide safe, comfortable, and reliable care for client horses. A quality setup builds trust and attracts long-term boarders.

Competition Venues: Spacious and well-organized facilities are ideal for hosting shows, clinics, and events. A competition-ready venue opens the door to new revenue opportunities while bringing the equestrian community together.

Breeding Operations: Breeding programs require specialized setups to meet the unique demands of their work. From foaling stalls to handling areas, every detail of the facility plays a critical role in a successful operation.

Therapeutic Riding: A controlled and well-maintained environment makes equestrian facilities an excellent option for equine therapy programs. The right space allows therapeutic riding organizations to operate safely and effectively, making a meaningful difference in the lives of their participants.

Ready to Get Started?

A steel riding arena is a long-term investment in your horses, your program, and your property. Year-round access, durable construction, low maintenance, and open riding space make it one of the most practical upgrades any equestrian facility can add.

Get started on your steel riding arena project, and request your personalized quote now.

Call Now: (888) 415-1576

![Indoor vs. Outdoor Horse Arenas: Which is Best? [Pros and Cons] Image for Indoor vs. Outdoor Horse Arenas: Which is Best? [Pros and Cons] post](https://www.uspatriotsteel.com/wp-content/uploads/2025/02/Photo-of-a-Horse-Arena-1-825x550.jpg)

![Indoor Horse Riding Arena Cost [Construction & Maintenance] Image for Indoor Horse Riding Arena Cost [Construction & Maintenance] post](https://www.uspatriotsteel.com/wp-content/uploads/2024/01/stable-9.jpg)