When planning a metal building, it’s tempting to focus on visible decisions like size, layout, or exterior finishes. Yet one of the most important factors – load calculations – often gets far less attention. This is where many costly mistakes begin. Wind and snow loads are the two primary environmental forces that engineers design metal buildings to resist, and each one affects a structure in very different ways. Understanding how these forces work, and how they differ, helps ensure your building is safe, code-compliant, and designed without unnecessary overspending.

What Are Structural Loads?

In simple terms, structural loads are the forces a building must safely support throughout its lifetime. These forces come from weight, movement, and environmental conditions, and they guide how a structure is engineered. For metal buildings, wind load and snow load are the most influential environmental factors.

Wind load includes sideways pressure against walls as well as uplift forces that try to pull the roof upward. Snow load works in the opposite direction, adding vertical weight as snow accumulates on the roof. Modern building codes require both loads to be calculated using standards such as the International Building Code and ASCE 7. Because metal buildings are relatively lightweight compared to traditional construction, they react more quickly to these forces, making precise load calculations especially important.

Wind Load Explained

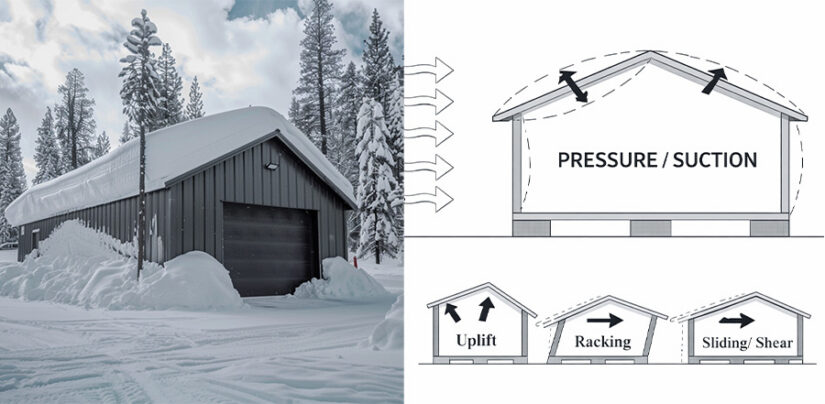

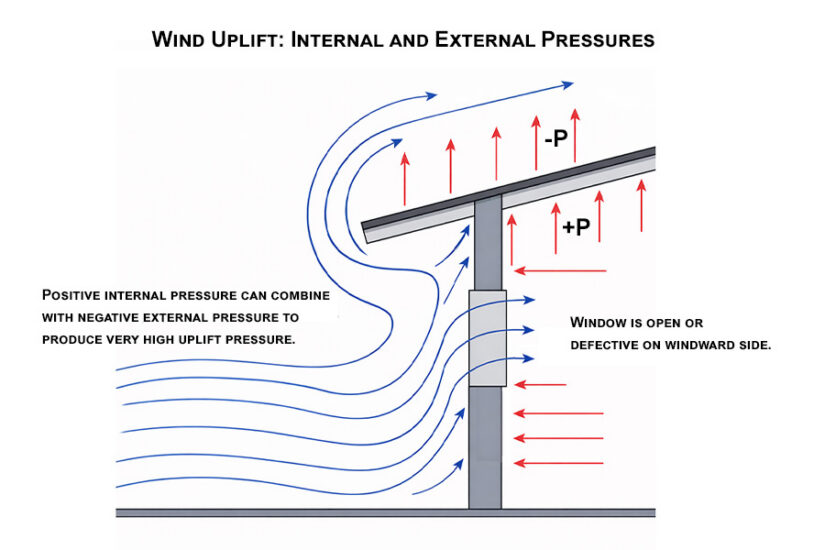

Wind is a dynamic force that rarely acts evenly. As it strikes a metal building, it pushes against the windward wall, creates suction on the opposite side, and generates uplift that can try to lift the roof from the structure. This uplift effect is often underestimated, yet it is one of the most damaging aspects of severe storms.

Several factors influence wind load, including regional wind speed zones, building height, roof pitch, and exposure. A tall building or one with a steeper roof catches more wind, while a structure in an open field experiences greater force than one protected by surrounding buildings or trees. Coastal regions face hurricane-level winds, Tornado Alley must handle extreme gusts, and open plains allow wind to build speed without resistance.

Engineers rely on wind speed maps and exposure categories to determine design requirements. To resist wind load, metal buildings often use enhanced anchoring, stronger bracing systems, and reinforced wall and roof panels to keep the structure stable under extreme conditions.

Snow Load Explained

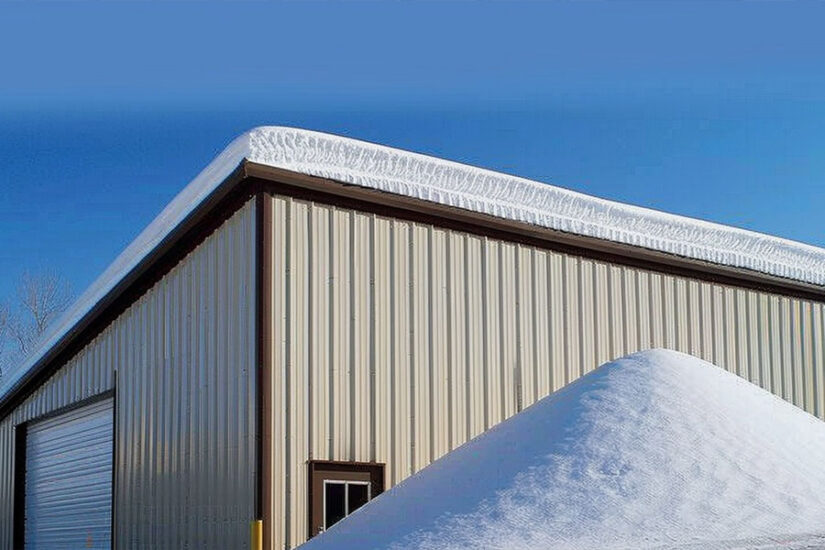

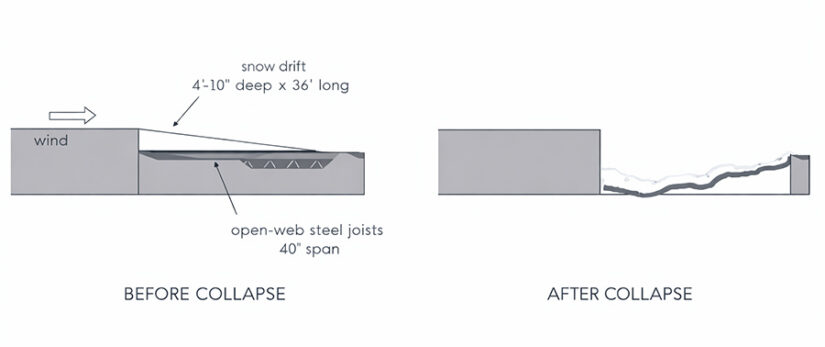

Snow load is the downward force created when snow accumulates on a roof. Unlike wind, which is sudden and short-lived, snow can remain on a building for long periods, steadily increasing stress on the structure.

Design begins with ground snow load, which reflects typical snowfall levels in a region. That number is then adjusted based on roof pitch, exposure, and thermal conditions to determine the actual roof snow load. Steeper roofs shed snow more easily, while flatter roofs retain it. Snow drifting is another concern, as wind can push snow into uneven piles, creating unbalanced loads that stress one side of the building more than the other.

Snow load is especially important in northern states, mountain regions, and areas around the Great Lakes. Engineers respond with stronger trusses, reduced column spacing, and sometimes steeper roof designs to safely support the added weight.

Critical Differences: Wind vs. Snow

Wind and snow loads affect metal buildings in fundamentally different ways. Wind applies horizontal pressure and upward suction, while snow applies vertical, downward force. Wind loads arrive suddenly, testing anchors, wall bracing, and connections in short bursts. Snow loads build gradually, placing sustained stress on roof framing and columns over time.

Because of this, different regions prioritize different loads. Coastal and open areas focus on wind resistance, while cold climates prioritize snow capacity. Each load challenges different parts of the building, and designing for the wrong one can lead to unnecessary costs or structural vulnerability.

Design and Cost Implications

Location ultimately determines which load governs the design of a metal building. Many sites require both wind and snow loads to be considered together through code-defined load combinations. These account for realistic scenarios, such as strong winds acting on a roof already carrying snow.

Designing for high wind loads typically increases anchoring strength, wall bracing, and connection hardware. Snow-driven designs usually strengthen roof systems, add framing members, or alter roof pitch. Trade-offs are common – a steeper roof helps shed snow but can increase wind exposure. Accurate site assessment is essential to strike the right balance between safety and cost.

Working with Professionals

For metal buildings exposed to meaningful wind or snow loads, involving a structural engineer early is essential. Engineers interpret local code requirements, evaluate site-specific conditions, and design for proper load combinations. Your metal building supplier will need accurate information such as location, dimensions, intended use, roof style, and exposure conditions to deliver a properly engineered building. Online calculators can help with early estimates, but they should never replace professional analysis for final decisions.

Conclusion

Wind and snow loads are both critical in metal building design, but they stress structures in very different ways. Wind challenges anchoring and lateral stability, while snow tests roof strength and load distribution. Which load matters more depends on location, climate, and building use. Proper engineering ensures the building is safe, compliant, and cost-effective without unnecessary overbuilding. For project-specific guidance and professionally engineered solutions, working with experienced providers like US Patriot Steel helps ensure your metal building is designed correctly from the ground up.